Imagine

|

||||||||||||||||

| I started studying Waltham Model 57 pocket watches and the predecessor company, the Boston Watch Company (BWCo), in the early 1990s. |

|

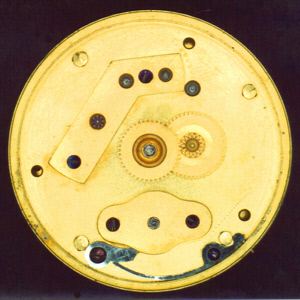

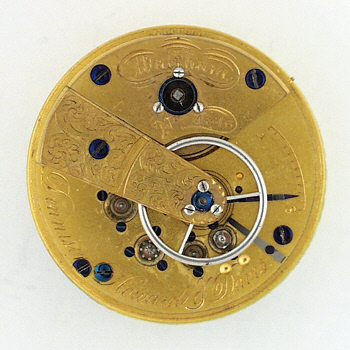

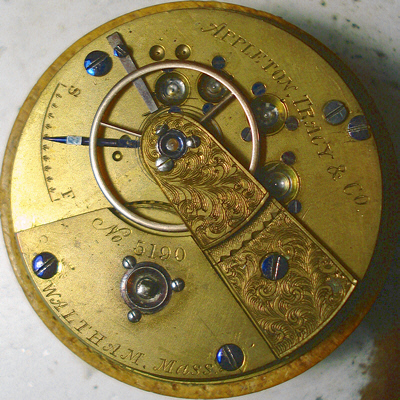

| Considering the literature available at that time, I had a mistaken impression of the company that it was mismanaged and produced maybe only a few thousand watches over 6 years. In fact, we now know this 1850s high-tech start-up company produced and sold nearly 5,000 watches and had over another thousand in the works when it went broke. Indeed, with a little luck and extra capital, it would have produced watches in the six thousands by 1857. This presentation is the outgrowth of tracking information about Model 57 watches for 20-some years, and the study of court documents when the BWCo went bankrupt in 1857. All of this information is in my online monograph, Origins of the Waltham Model 57, but the revelation of BWCo movements with serial numbers in the 6000s is new. Initially, the new company just renamed the BWCo movements and gave them a new number - just cosmetics. They looked just like the one shown here except with an actual number versus the edited No. 52mn (click image for larger view). |

|

And what did happen to the 1,000 plus movements in the factory when the BWCo went bankrupt? Answer: an intriguing story of discovery; who, what and where.

Preface

A quick and brief background of the BWCo will facilitate the presentation, but those who are familiar with BWCo can jump ahead (click here).

The use of automated machinery turning out interchangeable parts for watches on a large scale was first achieved in America in 1850s by the Boston Watch Company located in Roxbury, Massachusetts. Although not the first people to employ the use of machines in making watches, through Yankee Ingenuity, founders Aaron L. Dennison, Edward Howard, David P. Davis and Samuel Curtis were the first to put it all together and to start a major watch enterprise.

Unfortunately, like those who preceded them, their initial efforts were not financially successful. Indeed, early historians portrayed the company negatively. In the 1850s, the idea of producing 6,000 pocket watches was unheard of. As I will show here, the Boston Watch Company was much more successful than most previous historians gave the Company credit.

|

|

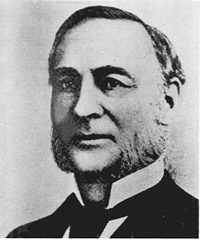

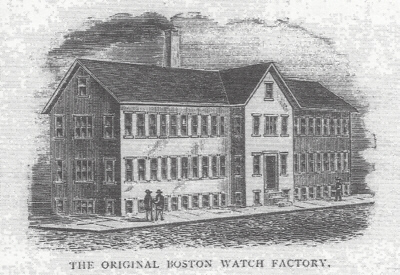

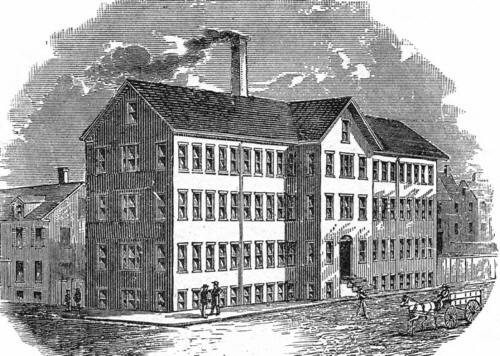

Aaron Dennison (left) convinced Edward Howard that they could manufacture vast numbers of pocket watches cheaply with interchangeable parts. After all, a watch is just a small clock. Here is a sketch of the factory in Roxbury, Massachusetts (sketch from Dawes' update of "The Complete History of Watch Making In America").

As most start-up companies find out, their initial thoughts are a little too ambitious. The company experimented with a few initial designs and finally settled on their signature movement called Dennison, Howard & Davis (DH&D), named after the founders (Davis was a partner with Howard, Samuel Curtis provided the initial funding).

The company moved to Waltham, Mass, in October of 1854 for wider spaces and a cleaner environment. Here is an anonymous artist rendition of the BWCo as it looked shortly after it opened in 1854.

DH&D movements started at serial number 1001. The first 100 or so movements were probably made at the Roxbury factory while the Waltham plant was being built. Otherwise, all DH&D watches were made at Waltham.

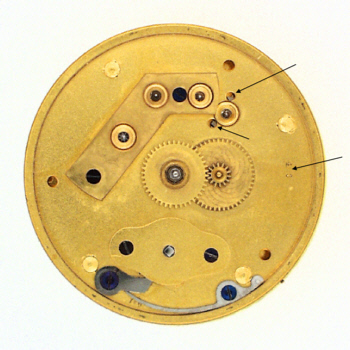

Here are pictures of DH&D 1016, movement top plate and pillar plate under the dial.

|

|

The highest surviving serial number I have recorded is 4887. I happen to have pictures for 4546, a fairly high number.

Movement top plate view (left) and pillar plate view under the dial (click images for larger view)

|

|

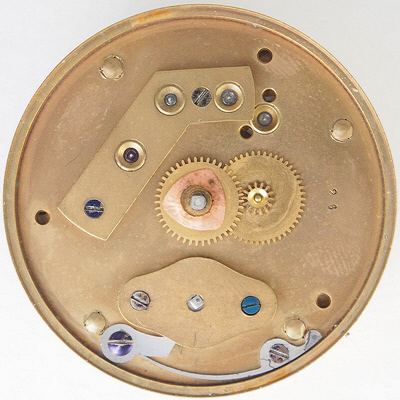

There were minor differences in the movements as the production evolved over time. The differences are documented in my monograph. For example, there are 2 “peep holes” on the latter pillar plate in which to see the escapement in action that the early versions did not have. Also note sub-assembly number 46. The steel wind guard was added around S/N 1600.

The move to Waltham was assisted by the Waltham Improvement Company (WICo) which managed the property; again, see my monograph for details. The WICo cosigned BWCo mortgages. This got the company in real trouble when it encountered hard financial times. Because of overdue debts and taxes, the WICo had to force the BWCo into bankruptcy in 1857, called insolvency then.

Supposition:

The company had a large amount of watch material on hand when it went insolvent. Indeed, the stockpiling of so much material is perrhaps an indication of mismanagement and one of the reasons the company failed financially. Royal Robbins bought the company at the insolvency auction on May 9, 1857. My supposition is based on the belief that Robbins incorporated much of this leftover material consisting of plate assemblies and movement parts to make his first Appleton Tracy movements in the beginning days of his famed American Watch Company (AWCo), in fact 800 specific movements, a sizable number.

I will now present evidence from surviving movements and insolvency documents to show that BWCo serial numbers exist in the 6000s.

Take a look at the movement of Dennison, Howard & Davis (DH&D) 4546 (left). Note the markings on the barrel bridge and on the plate, the word “Waltham” and number on barrel bridge facing center, and signature on plate facing edge.

|

|

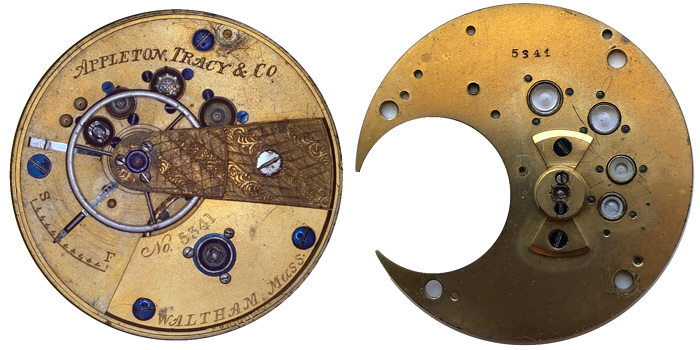

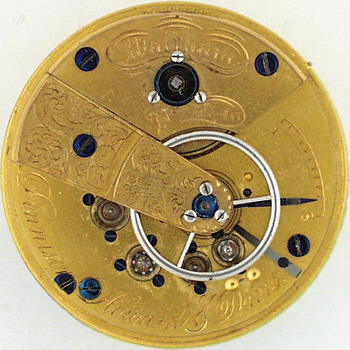

By observed surviving watches from the new company, it looks like the first 100 movements were exact DH&D copies except for the name AT&Co (AT). Robbins produced these movements starting in July of 1857. First number is 5001. View of AT #5026 movement is on the right. Markings on barrel bridge still the same, facing center; new signature facing center instead the edge. Everything inside still the same.

Here is pillar plate view of AT 5026, same as prior DH&D pillar plate. Same location of sub-assembly number (26), same click, peep-holes, etcetera.

Markings on the barrel bridge of movements made in August and later have a new style which became the standard AT&Co appearance till the mid-1860s. See AT data sheet. Here is movement view for AT #5190 (permission of owner).

Note Waltham (+ state Mass) lettering and number on barrel bridge facing edge instead of center.

The movements, however, were still basically DH&D movements with the same internal parts, including, for example, the potance mounted under top plate and the stamping of the full four-digit serial number on the underside of the top plate at the same general location.

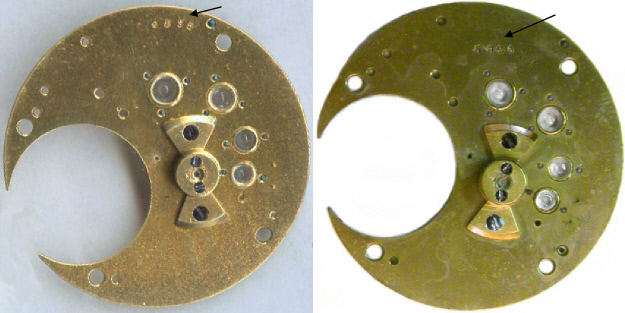

The potance supports the bottom balance arbor. DH&D on left, AT on right.

As documented in literature and in "Origins", Edward Howard had hoped to buy the failed company at a bargain price and continue manufacture under his control. Charles Rice would finance the operation; Rice held a mortgage on the contents of the factory and was a major creditor at the auction. As documented, Howard lost the auction and Rice raided material out of the factory claiming he had right to the material. Howard then made his famed Howard & Rice watches (H&R) back at the original Roxbury plant by incorporating the BWCo material, about 500 movements total according to my H&R data sheet, including several signed E. Howard & Co.

Here is sketch of the Roxbury Factory, actually after 1857 (from Henry Abbott's "A Pioneer" History of the American Waltham Watch Company).

The fourth floor must have been added to the factory after 1857 because Howard didn’t exactly own it in ’57; it was under insolvency proceedings for two years. After the proceedings were settled, he purchased the adjacent back lot on Oct. 1, 1860, (left side of picture) which in this sketch shows a building on it. Interestingly, no one argued that Howard did not have the right to go back to the Roxbury building to continue manufacturing. Although Howard had to make amends for his insolvency, he (and Davis) had original deeded rights to the property; Dennison did not..

Howard’s H&R watches looked a lot like DH&D watches; no surprise, but they, of course, had several enhancements. First number probably 6001. Here is photo of an early H&R movement #6011 (click image for larger view).

Note, for example, the two screw-adjustable banking pins which the DH&D movements did not have. Howard cannibalized seized DH&D movements and parts from the bankrupted company to make these movements.

DH&D #5000 is a divided-plate movement like E.Howard & Co. Series I&II movements. It might have been a prototype for future production that Howard wanted if the BWCo had survived. I doubt Dennison had much interested in it because he had many DH&D plates already made and stamped with serial numbers far beyond 5000. It was probably commissioned by Howard, which is another indication of discordance among management of the company in 1857. I suspect Howard didn't want to be associated with the design of the DH&D movement because when he moved back to Roxbury from Waltham he added many features to convert a DH&D movement into a H&R movement.

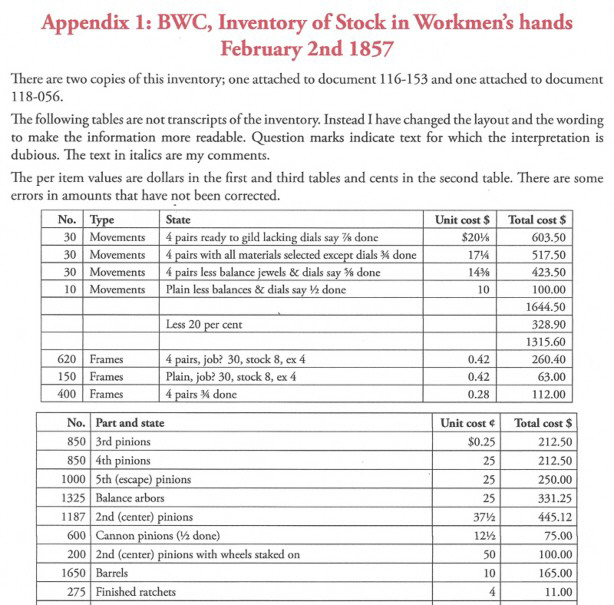

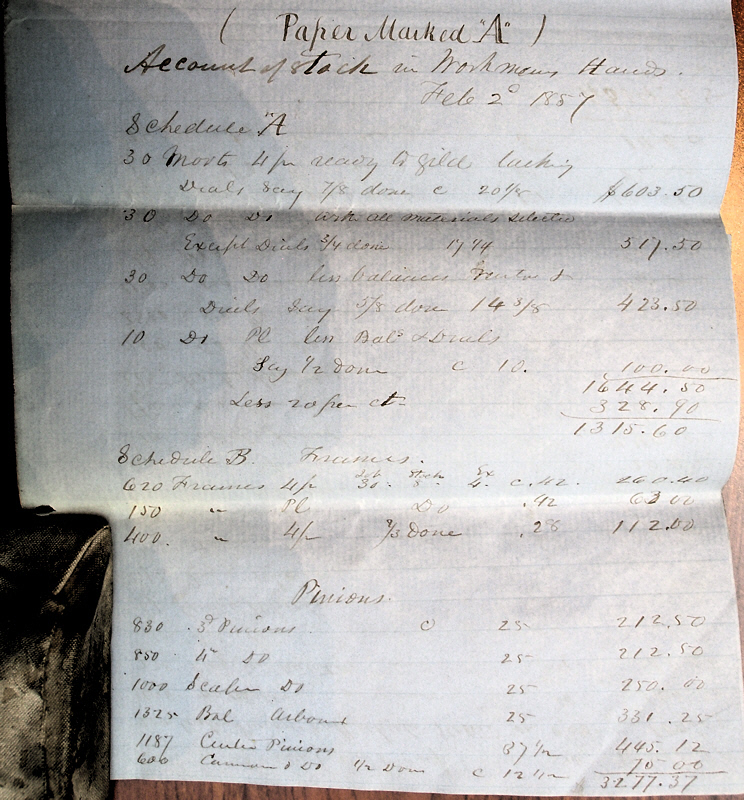

Getting back to the insolvency. On February 2, 1857, an inventory was taken of the contents of the BWCo factory. I guess this inventory was requested by Rice because he used the inventory as collateral for the loan he gave the company. The total value of the inventory was $7,510.49. Fortunately for us, this inventory was written in a detailed document which was submitted in an insolvency court case after the auction. The document survived in court archives. [refs-notes, case 116, sheet 153] Here is image of the first page.

I uncovered these insolvency documents in August of 2002. Back then I was not allowed to photo copy them; I could only take notes with pencil and paper which I put in my "Origins" monograph. Later in June of 2018, contributor Richard Watkins arranged to have the documents retrieved again. Interestingly, he did this from his home in Australia. So then, Bob Frishman (of Bell Time Clocks) and I went to the Mass Archives in Boston to photograph a number of the documents. This time we were able to do it digitally without additional lighting that would harm the papers.

It is not all that easy to read these original documents, especially from the photographs. Richard transcribed them, which made their study easier. Here is scan of the top part of first page of Richard’s inventory document (click for full page). There are three pages in total. Richard Watkins transcriptions in Cook Rice and Potatoes (http://www.watkinsr.id.au/CookRicePotatoes.html); inventory is Appendix 1.

The inventory consisted of a vast amount of watch parts, around 100 partial movements and 1,170 frames that could be completed into finished movements fairly quickly. Frames were partially finished pairs of plates apparently already stamped with serial numbers. The term “frames” must have included their attached parts like pillars, barrel, barrel bridge, balance bridge, potance and third-wheel bridge because these parts were not otherwise listed in the parts inventory. Also apparently, the parts were screwed together because plate screws were not listed in the inventory. In other words, a frame is the structural component of a movement.

Plates must have been pre-drilled for jewel settings for the "4 pair" listings (15J movements); the listing marked "plain" would be for plates without holes for jewels (although I suppose jewels could have been added later for 11J movements).

Although not relevant to my supposition, most (if not all) of the early AT and H&R movements had the center pillar arbor hole set with a jewel. (Data sheets in "Origins" list these movements as 16Js.) I think the BWCo was starting to jewel this arbor at the end of production, but we have not yet seen any DH&D examples probably because this jewel is hard to observe, or to even be aware of it, if you are not looking for it.

According to several examples seen with these early movements, the underside of the barrel bridges are not stamped with their sub-assembly number because the full serial number is applied to the top. For example, see DH&D 4915 and AT&Co 5040 entries in their respective "Origins" data sheets. I believe this number on top is engraved, not stamped. It looks engraved to me. Moreover, the style of the number looks different than the number stamped on the underside of the top plate. Indeed, the fonts are different as can be clearly seen in the example below for AT&Co #5341's top plate (click image for larger view).

The time period “fairly quickly” is relative because there were not enough other parts like wheels, jewels and escapements that had to be made to complete 1,170 movements. Nevertheless, the large number of leftover frames is significant, especially because they consist of top and bottom plates with their attached parts.

We can expect various items would have been added to and taken from the inventory during the three-month period up to the auction of the company on May 9, but activity in the factory had to have been highly curtailed in this period, if not shut down, because officers of the company filed petitions for insolvency in court a month earlier on April 15. Moreover, the WICo foreclosed the mortgaged BWCo properties two months earlier on March 3.

Consequently, I believe this February 2 inventory is a valid estimate of the material that existed on May 9, not necessarily the same material, but the same amount.

It is important to note that the inventory document is titled “account of stock in workmen’s hands.” This inventory was just for works in progress, not completed products. Although balance springs and mainsprings, for example, are certainly key parts in movements, they are not listed in the inventory. Apparently, these parts were not made by “workmen” in the factory and were probably purchased and stored in a safe or locked office area that did not get documented in the insolvency papers. Ditto for dials. Completed movements to be sold might also have been stored in this office area.

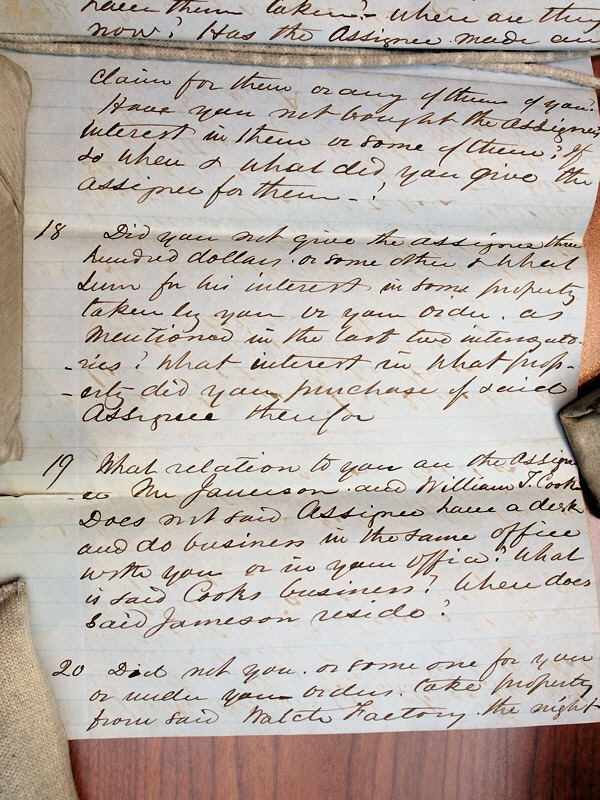

According to insolvency court documents, Charles Rice, probably with help, was accused of taking material and tools out of the factory illegally, perhaps even during the night before the sale. Here is image of the accusation; it is question number 20 of case 116, sheet 153 (also see case 118, sheet 56, involving Howard). There were a lot of papers to view. Even a so-called “sheet” could consist of multiple pieces of paper.

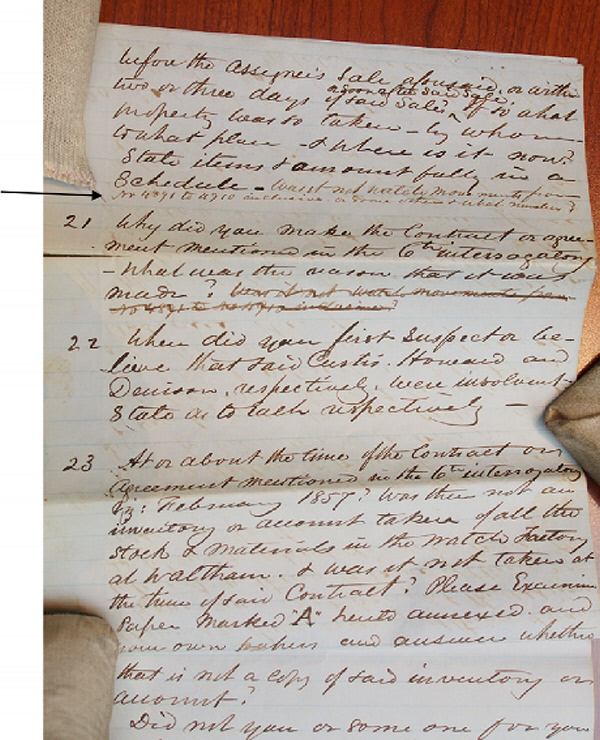

You can see at the bottom it reads “Did not you, or someone for you or under your orders, take property from said Watch Factory the night”. Unfortunately, this item goes across two pieces of paper. Here is next page.

Of particular note here is that Rice was specifically accused of taking 20 movements numbered 4891-4910. (in the fold of the paper near top) So, the company had manufactured just 90 short of 4,000 DH&D movements (maybe 85 movements short, see #4915 below).

Rice claimed ownership of the inventory he took because it was collateral for the loan he had given the company. However, Rice could not have had rights to any inventory left in the factory because all mortgages and leases would have been resolved by the insolvency assignee before the sale. The assignee, Nathan Jameson, a merchant in Antrim, NH, was appointed on April 16, 1857, a day after the insolvency declaration. Indeed, Jameson later listed Rice a creditor and owed a lot of money, much more than even the value of the February 2 inventory; e.g., [ref. 106, case 116, sheets 175 ($26,556.60 ) and 176 ($7,607.23)].

There is some evidence, although not clearly documented in the literature, that Robbins bought back some of the material from Rice to save time instead of fighting Rice in court. In book Timing a Century, Charles Moore lists Tracy Baker & Co.’s May 1857, cashbook with an expense of $2,359.82 for “material & work not finished”. [ref. 51, p. 315] Although not stated, the seller was undoubtedly Rice. The amount of this “expense” was 1/3 of the February 2 inventory value ($7,510.49) minus the silver, which could have included hundreds of frames listed at $0.42 (e.g., 800). Where else was Robbins going to get a lot of useable watch parts in May of ‘57?

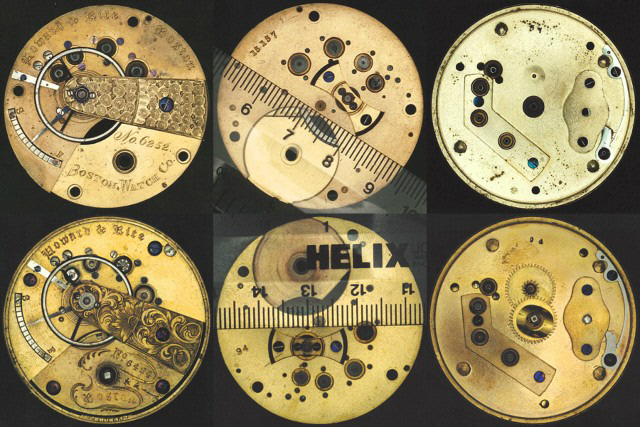

We can get an idea of what happened to the plates leftover from the insolvency by observing the BWCo serial number on the underside of top plates. Here is a view of the underside of top plates for AT (left) and H&R (click for larger view).

When recording surviving early AT&Co movements and H&R movements, I also tracked the original BWCo serial numbers underneath the top plate, when I could get the data. The example here is for AT&Co 5026. Note the number is 5826, interesting. The right-side example is for H&R 6011. Note the number is 14983, interesting. For some treason Howard added the digit '1' in front of the original BWCo serial number, in this case 4983, a very high number for DH&D. [I believe Howard added the digit "1" to the BWCo number to distinguish his movements from BWCo movements but still kept the BWCo subassembly numbers.]

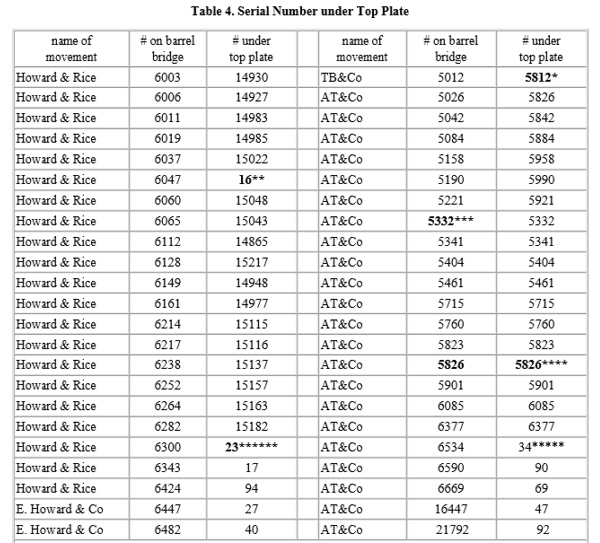

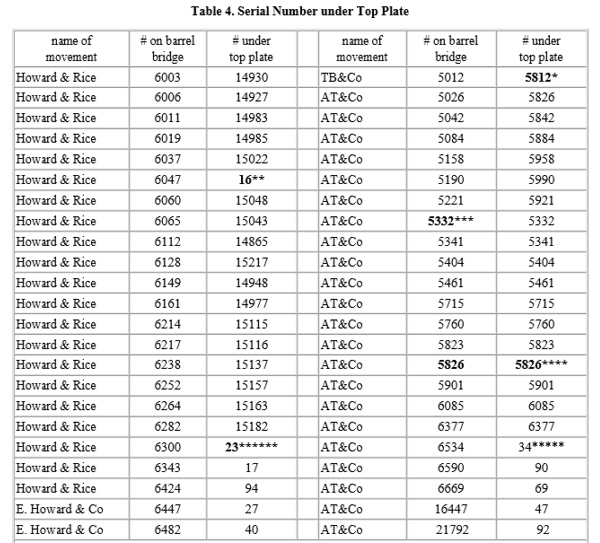

After getting a good number of examples, a consistent pattern became apparent. Here is Table 4 in my monograph of BWCo #s.

Left side is Howard’s H&R movements with movement number followed by number under the top plate; right side is same layout for Robbins’ AT movements.

According to the BWCo serial numbers of Howard & Rice movements, it looks like Howard started using BWCo movements around high numbered 48hundred (e.g., 4865 from H&R 6112). This is supported by court interrogatories where Howard and Rice were accused of taking specific movements #4891 to 4910 out of the factory. Howard also incorporated BWCo frames with serial numbers in the 49hundred range (probably frames versus movements, e.g., 4985 from H&R 6019) and frames in the 52hundred range, perhaps as high as 5300 (e.g., 5217 from H&R 6128). Altogether, this was enough material to make around 400 H&R movements. Roughly 100+ DH&D movements and frames (e.g., 4865 - 4985) and 300 high frames (e.g., 5001 - 5300).

However, by observing the difference of the engraving on H&R plates and of the different two-digit sub-assembly number under H&R top plates around H&R #6300, it looks like Howard abandoned BWCo plates after the first 300 H&R movements and started making his own plates for the remaining 200 H&R movements. Next picture shows comparison of H&R plates before and after 6300 (click for larger view).

Sorry for the crowded picture, 6252 on top, 6424 on bottom. Note difference of the lettering on the movement top plates, especially just Boston instead of BWCo. The middle view is of the underside of the top plates, the right view is of the pillar plates. The 6252 plates have the standard DH&D numbering including the sub-assembly number 57 on the pillar plate. The lower set of 6424 plates have a sub-assembly number 94 on both under top and pillar plates; the location on the underside of the top plate is on the opposite side of the plate.

This design change signified a change in manufacturing. No BWCo movement had this numbering. This change would be near the end of year 1857. Even Robbins was manufacturing his own movements by then.

Richard Watkins got me to start thinking about this subject some time ago. He was drafting then an article on the production of the BWCo. When trying to reconcile Table 4’s BWCo numbers with the inventory document, I struggled to get 500 H&R movements out of this inventory. Then it dawned on me that Howard used only enough BWCo plates (from movements and frames) to make 300 H&R moments. Robbins’ situation also than began to fit, and my supposition was on.

The supposition that Howard took no more than 300 BWCo frames up to #5300, whether he used them or not, is critical to my thesis.

Considering Howard started with approximately 400 movements worth of plates, it looks like he abandoned a good number of plates, especially frames in the range of 52xx. He was interested in providing better features, and starting anew might have been easier than reworking old material. Many H&R movements have been reported in "Origins" with sub-assembly numbers stamped on the underside of their barrel bridges which is not the case with BWCo bridges. He probably did this because there is no correlation between H&R serial numbers and BWCo serial numbers. He also had to rework BWCo plates in movements to remove old engraving; again necessitating the need for the sub-numbering. [I haven't had opportunity to measure thickness of plates, except for one example; plates on H&R 6149 (BWCo 4948) have the same thickness as the plates on AT&Co 5341, although not knowning the tolerance of plate thickness I might not be able to discern a difference. However, H&R 6149 (BWCo 4948) might have come from a frame versus a completed movement and might not have been engraved as explained later.]

Interestingly, BWCo movement #4915 survived (in part, i.e., the barrel and balance bridges; see DH&D data sheet in "Origins"). It must not have been a completed movement Howard took out of the factory before the auction because it was not listed in the insolvency papers (#s 4891-4910 were), so it must have been a nearly completed movement that was engraved and guilded after the Feb. 2, 1857, inventory (the inventory lists movements to be guilded). Howard did not use 4915 (bridges) because it is signed "Waltham" (see picture).

Changing subjects for a moment, it looks like Howard and Rice kept all BWCo cases. There were, for example, 138 partially completed hunter cases in the February inventory. This makes sense because Howard kept the name. He used these cases to house H&R movements, as shown in my monograph. There is no evidence yet that I have seen of any BWCo case originally housing any AT&Co movement, but maybe we have not yet seen enough examples.

Getting back to the table of serial numbers under top plate:

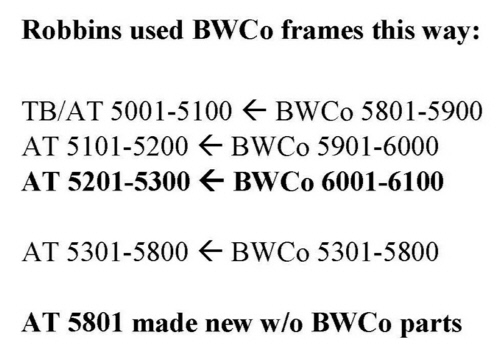

According to Table 4, it looks like Rice kept the low numbered frames and leftover movements, and sold Robbins BWCo frames starting around S/N 5300; specifically, it would have been 5301. By extrapolating the data, I believe Robbins used BWCo frames up to as high as S/N 6100, enough for 800 movements. This is consistent with the inventory document, including Howard keeping 300 frames.

Again, from the above table 4, Howard used BWCo frames (probably in movements) as low as 4865 and as high as 5217. These frames are not in sequence as Robbins used them, but apparently Howard was more concerned about adding features than about maintaining sub-assembly numbers in sequence.

There are a couple of problems in Table 4 that need to be corrected. In particular the BWCo number 5921 for AT 5221 is incorrect, I hope. It should be 6021 to be consistent. Note the Pattern: 58hundred BWCo frames for 50hundred AT movements, 59hundred BWCo frames for 51hundred AT movements, so then we could expect 60hundred BWCo frames for 52hundred AT movements.

I guess I should expect some outliers, but I’ve really got my neck stuck out here. I’ll have to rethink my thesis if I don’t get favorable 52hundred examples. I suppose #5221 could be a mixed parts movement, but this does not seem likely.

Long time ago in 1995 the owner of AT 5221 told me the number on the underside of its top plate was 5921. This was in response of hearing my theory that these underside plate numbers on early AT and H&R movements were the original BWCo serial numbers. At that time in 1995, examples existed for underside plate numbers 5884 and 5958, and no one ever heard of a BWCo #6000. Perhaps the owner, thinking of 58hundred and 59hundred numbers, misread the actual number #6021. The underside plate number can be seen simply by looking between the plates with a loupe and good lighting, but it can be difficult and some numbers might have been reported in error.

Another problem with Table 4 is the AT 5332 entry. Note the abrupt change with the BWCo serial number under the top plate. When I built Table 4, I hadn’t yet thought through the analysis I’m presenting today and extrapolated the data. I thought at that time, that Robbins ran out of BWCo plates at 5300. No, I’m saying now he started with 5301!

This said, this is how I believe Robbins used BWCo frames to make his first 800 movements.

Note the first 300 movements used different 300 BWCo series. To be consistent in batch order, Robbins used BWCo frame #5301 for AT movement #5301, and used frame #6100 for AT #5300. This is a little complicated, but note that Robbins having available 800 frames, if Robbins had started using BWCo frame #5301 for his first movement, 5001, all 800 movements would have been out of sync between AT and BWCo numbers. This way, as shown, only the first 300 movements are out of sync, and the last 500 numbers are identical and continue on through 5800 when Robbins made his own movements. This is supported by Table 4. Note also the BWCo sub-numbers on the first 300 movements are identical to the AT&Co numbers.

In support of this proposal we need to visit the guilding process. The common belief as I understand, is that movements were engraved after being guilded versus the other way around. The fact that the "57" Inventory report lists movements not yet guilded but no such mention is made for frames, supports this belief. This process would facilitate making private label movements, and would make Robbins' job easier converting BWCo frames (not yet engraved DH&D) into AT&Co frames (same as making private labels).

However, I have seen a lot of DH&D and AT&Co plates and I cannot say for certain which way was done, although my eyes very much favor engraving just before guilding. Also, considering that the barrel bridge has to be engraved with the serial number on top, how could it be safely guilded separate from the top plate without its serial number on top or underneath. Therefore please note, Robbins was using frames, not "completed movements". I suggest frames were engraved, then guilded during the process of making completed movements. Therefore, if the BWCo frames were not engraved, this proposed order of how frames were used did not require any additional work.

Robbins could have conceivably gotten frames higher than #6100 which he discarded or cannibalized, but over 70 would be inconsistent with the Feb 2 inventory if taking its total (1,170) literally; besides AT&Co movement #5800 (the 800th BWCo leftover movement) was finished at the end of 1857 when Robbins was already making new movements (Parkers and Bartletts). If he did have some extra frames and used them as is, then for example AT&Co #5332 would have BWCo serial number 6132 and not 5332 as reported; ditto similarly 5341.

So, there you have it, 101 AT&Co movements with BWCo serial numbers in the 6,000s. Assuming the AT&Co survival rate is comparable to the DH&D rate, there could be 10 or so happy owners.

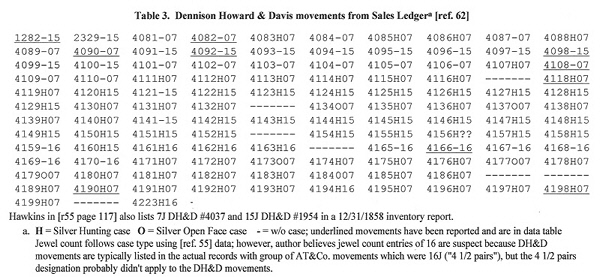

Okay, I bet someone wants to ask, what about the DH&D movements Robbins sold as documented in sales records [ref102]. Table 3 in my monograph.

Starting in June 1857, Royal Robbins sold approximately 120 DH&D movements through September 1857 (plus a few later). These movements were numbered on a low side (e.g., 4081) compared to surviving high numbered DH&D movements. The factory started manufacturing new movements in July, and sold, which I contend came from the insolvency inventory material. That is, Robbins did not cannibalize DH&D movements because his new watches had 16 jewels and high numbered internal BWCo serial numbers.

Again, although speculative, there is evidence that Rice did not take everything loose in the factory. There is the matter of tools and fixtures which have been written about elsewhere; not a subject here except to say there had to be a limit of how many items Rice could physically remove and time in which to do it. This was not a trivial event. The watch material alone would weigh upwards of a hundred pounds and require a lot of boxes. Many small parts might have been left in the factory because Howard did not want them; e.g., escapements and regulators (Howard made his own versions). More importantly, I believe there was an office area, maybe “sales”, containing completed movements and purchased parts that Rice knew he did not have rights to, was locked, or whatever.

I believe these 120 or so movements (Table 3) remained in sales at the time of the auction which Rice & Howard did not take. Robins took position of these movements and sold them mostly in June through September, 1857. How else could Robbins’ cache of DH&D movements be explained? Completed movements do not fit the definition of “material & work not finished” that Robbins bought from Rice. These movements were many hundreds in serial number below those cannibalized by Howard. So, Howard did not have them.

This idea of a “sales office” is consistent with my thesis.

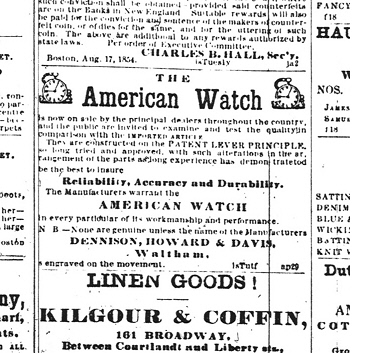

Many DH&D movements survived with serial numbers between Robbins’ cache and those cannibalized by Howard. By serial number, the BWCo could have produced around 600 movements in this range. In fact, more than 10% have survived. According to my DH&D data sheet quite a few high numbered movements have survived (e.g., 4887, 4883, 4876, 4855, 4849, 4841, 4814 4810); 8% of the 48hundred range. Who sold them? I claim the BWCo sold them. Heck, the Company was advertising weekly in local newspapers the sale of their watches as late as April 14, 1857. Here is an example ad in the Boston Post.

Of course, we do not know when the ad was placed, but it is a good indication that the Company at least had the capability to sell watches in the early days of 1857.

Of course, we do not know when the ad was placed, but it is a good indication that the Company at least had the capability to sell watches in the early days of 1857.

I suppose Robbins could have sold these movements in addition to those in Table 3 privately and hidden from Company records, but that would be a very big stretch. Of the 20 movements Howard had as reported in the insolvency documents (4891-4910), none have yet been known to survive. I assume they were cannibalized to make H&R movements. I seriously doubt Howard sold them. Considering the vast research done on Howard & company, there has yet been any evidence that Howard sold DH&D movements, especially in significant numbers. Maybe a few movements he had but did not cannibalized, but not 600 movements. And I note Charles Rice was not in the business of selling watches; according to E. Tracy, he was a shoe merchant [ref. 6 - page 274].

I admit my story is highly circumstantial and speculative. Indeed, why would the BWCo stockpile the 120 Table 3 movements, and sell movements in the high serial number range? I hope my story is at least reasonable. I Believe if you own an AT&Co movement in the range 5200 - 5300, you own an original BWCo in the 6000s!

Does anyone know the whereabouts of an AT 52hundred?

I have to get my digs in here. The Boston Watch Company was much more successful than most previous historians gave the Company credit. It is fascinating to think that if the company had acquired additional capital in 1857, there would have been a DH&D pocket watch with serial number 6000. Even so, the rift between the founders, Edward Howard and Aaron Dennison, was so large, I believe the company would have eventually broken up anyway. In which case maybe Royal Robbins never would have gotten involved. Maybe the American Watch Company never would have come to be. And maybe one of the greatest industrial enterprise the world would see in the 19th century would not have happened. Although ugly at the time, the financial failure of the BWCo in 1857 turned out to be a very fortuitous event.